Electric Drives

Electric Drives

The laboratory of electrical drives and power electronics specializes in testing electric motors, power converter and control system both for industrial applications (traction, grid interface) and automotive applications (hybrid and full electric vehicles). Thanks to two different test-rigs, electric drive of a power up to 100 kW and torque up to 1500 Nm can be tested. Thanks to our expertise, customized (high-efficiency) power electronics hardware based either on silicon or wide-bandgap semiconductors can be developed tailored to the customer's requirements. Moreover, the lab offers wired or wireless condition monitoring solutions for power electronics equipment, railway vehicles and infrastructure.

INSTRUMENTS & FACILITIES

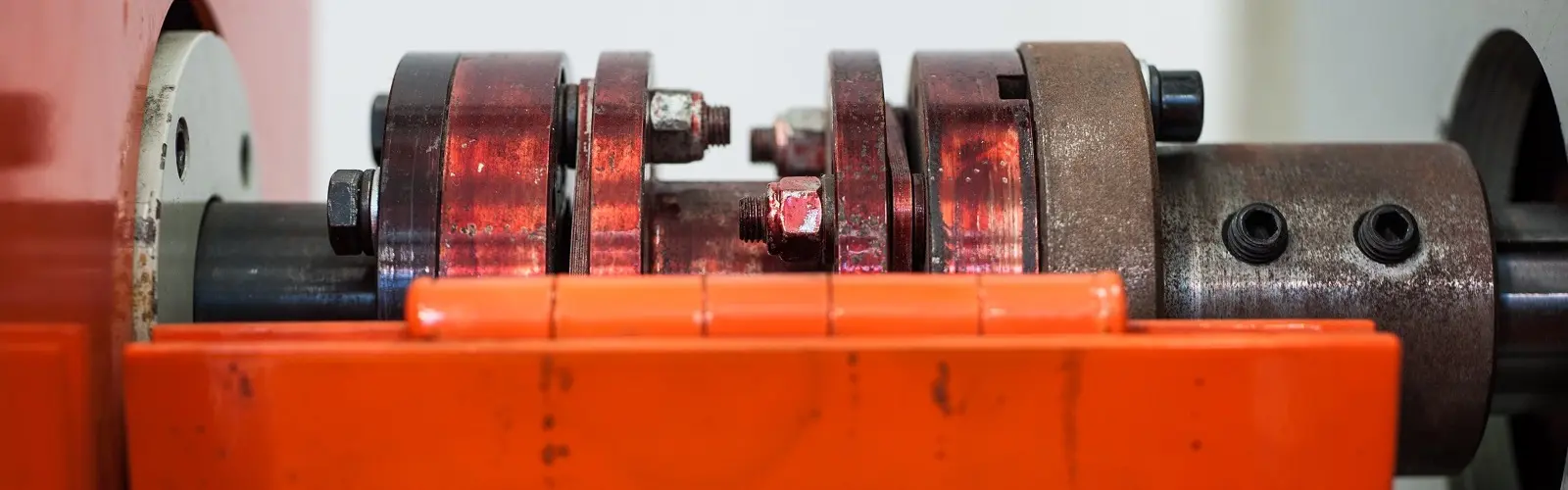

- 100kW Motor test bench (2500Nm/6500 rpm)

- Regenerative Motor Test Bench (35Nm/7500rpm) with PC based Data Acquisition and Control system and Power Analyzer Yokogawa PZ4000

- Power Supply Units (1500W): 600V-2.5A; 300V-15A, 12,5V-120A

- E4360A Modular Solar Array Simulator Mainframe, E4362A Solar Array Simulator DC Module, 130V, 5A, 600W

- dSpace Real-Time board for electrical drives prototyping

- Scopes, Current probes, Insulated Voltage probes, Industrial Electrical Drives, Laboratory Power Supplies

- Development system for Embedded hardware and software (Microchip, Freescale, TI, STM) and Static Converters.

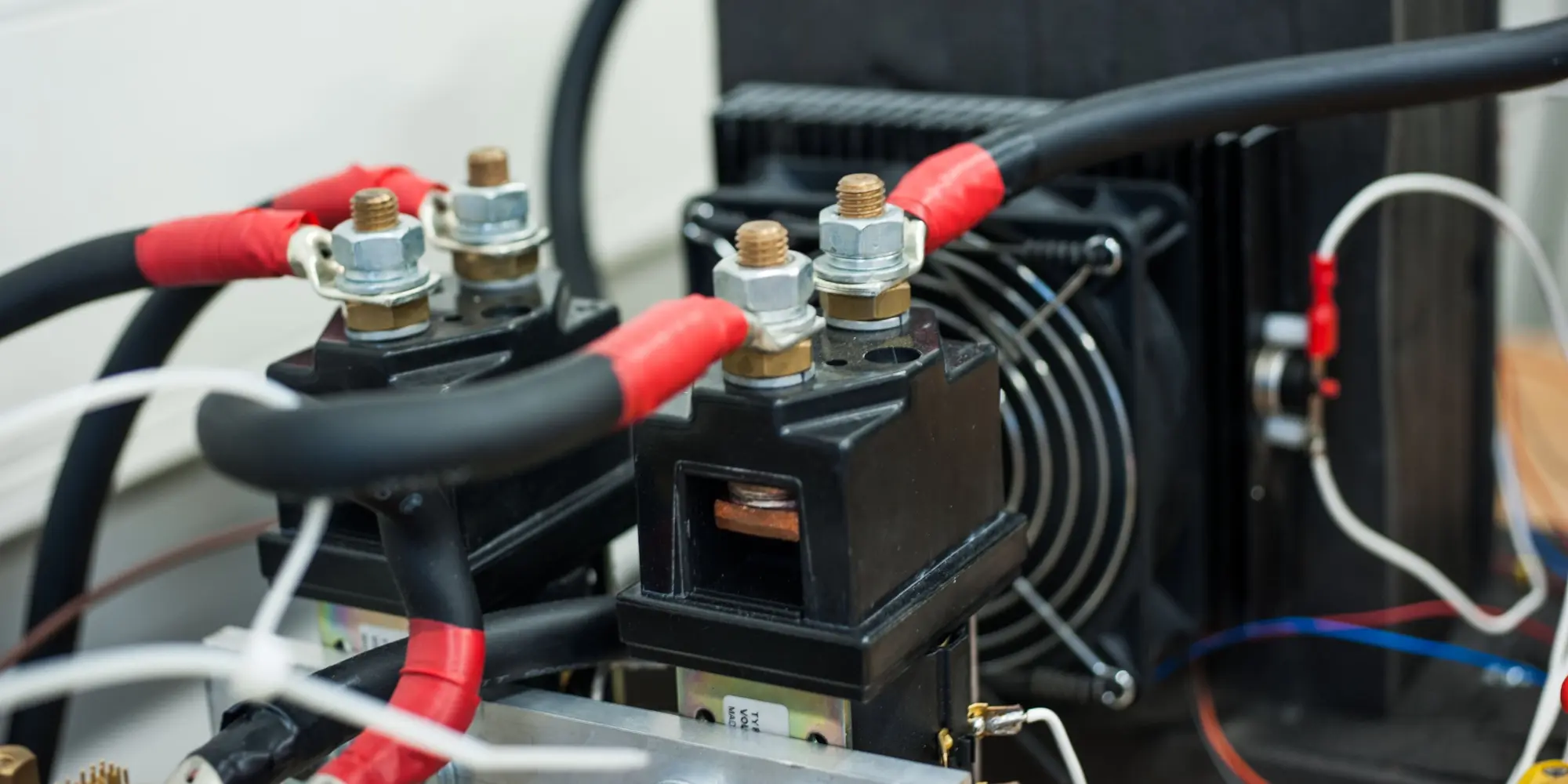

- 30kW IGBT-based three-level T-type three-phase converter with sensing interface (ETH, CAN, UART)

- 35kW IGBT-based H-bridge two-level converter module with sensing interface (aimed to modular connection towards MMC topologies)

- 20kW SiC-MOSFET-based two-level three-phase converter with sensing interface (ETH, CAN, UART)

- Modular LCL-filter with distributed sensors and related interface (ETH)

- Teaching kits for university students and/or academic initiatives: motorcontrol kit (BLDC, IM), power conversion kit (DC-DC, PV, MPPT)

ACTIVITIES

HSD AC motors high efficiency electric motor testing

- No load test and magnetizing curve

- Parameters identification test

- Load test, efficiency measurement and thermal behavior

- Full speed test in field weakening condition

- Test on AC induction and AC permanent magnet synchronous motor

Electric drive test for household application

- Parameters identification test

- Load test, efficiency measurement and thermal behavior

- Full speed test in field weakening condition

- Test on AC permanent magnet synchronous motor with vector sensorless control

Solar Simulator

- MPP Validation

- Solar Inverter Tests-Rig

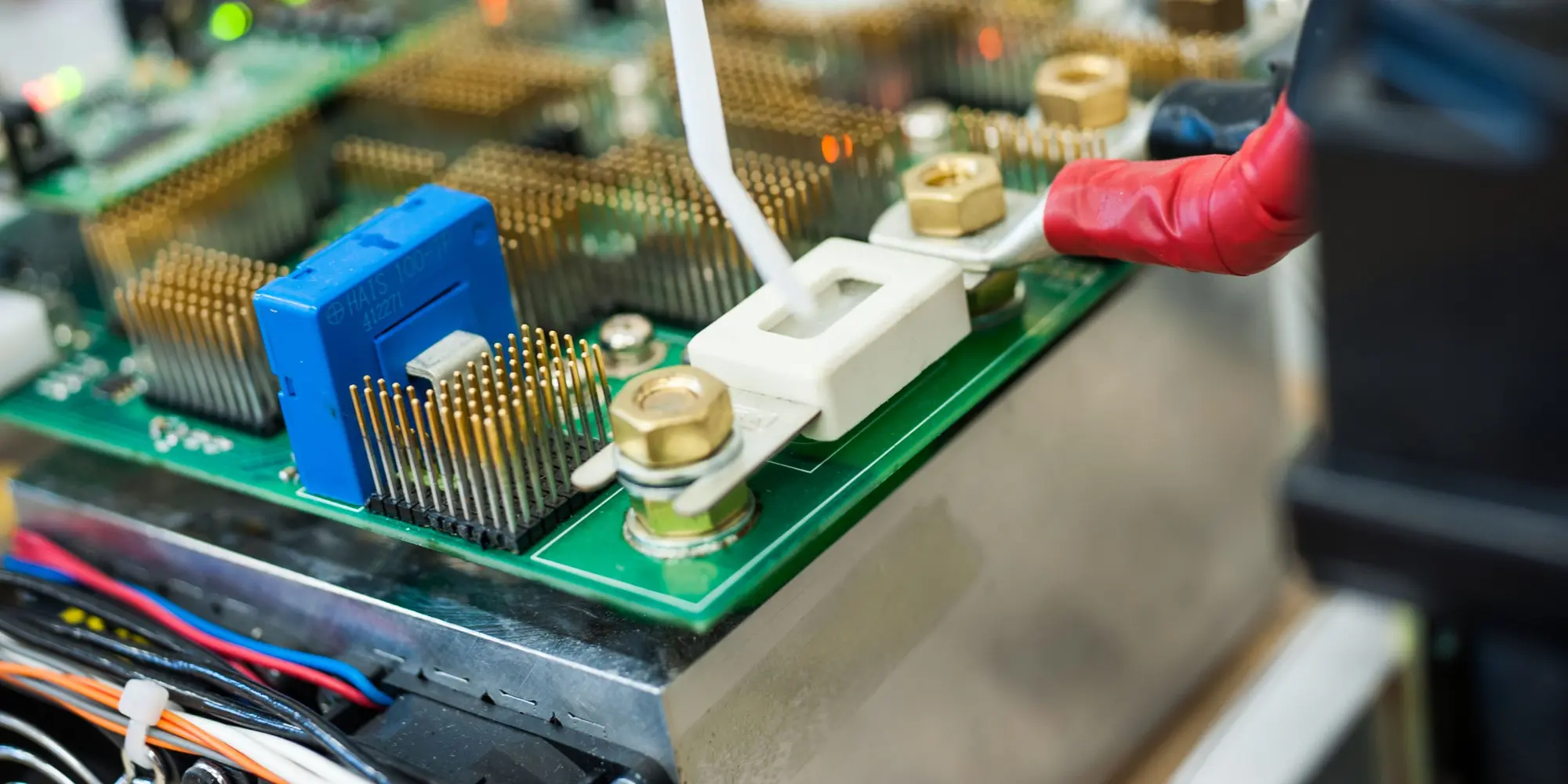

Methods to achieve enhanced reliability of power electronic systems

- Reliability model of most fragile components of power electronic equipment used in traction drives and grid interface

- Development of wired or wireless solutions (e.g. BLE) for condition monitoring of power electronics equipment

- Development of customized (high-efficiency) power electronics hardware based either on silicon or wide-bandgap semiconductors

Methods to improve the safety and reliability of railway vehicles and infrastructure

- Development of wired or wireless solutions (e.g. BLE) for condition monitoring of trains and infrastructure

- Development of customized smart sensor nodes for low cost and high flexibility (edge computing) monitoring systems

01/02

02/02