Start

28/09/2023

End

27/09/2025

Status

In progress

MAGELLANO - MAnufacturing systems for Graphene nanocompositEs and their appLications as embedded eLectrochemicAl seNsors in Lab-On-chip

Start

28/09/2023

End

27/09/2025

Status

In progress

MAGELLANO - MAnufacturing systems for Graphene nanocompositEs and their appLications as embedded eLectrochemicAl seNsors in Lab-On-chip

Graphene nanocomposite have been widely developed for a wide range of electronics devices. Usually, these applications require the deposition of modified graphene on a prefabricated device. To this aim graphene functionalization steps (e.g. oxidation) are necessary to make the nanomaterial compatible with the dispersing phase facilitating its manipulation and deposition. However, this procedure dramatically affects the mechanical and the electronic properties of the graphene thus

irreparably compromising the final performances of the material. Moreover, these methods are

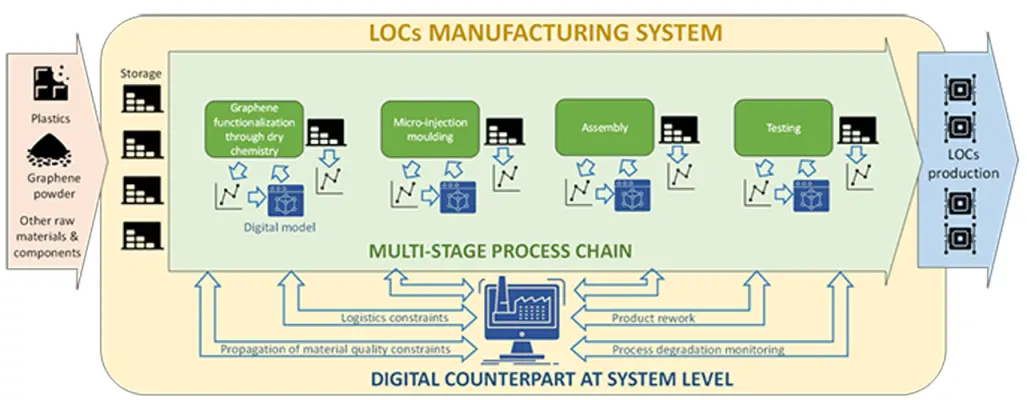

poorly scalable and limited to few types of architectures thus inhibiting the industrial diffusion. This is in countertrend with the numerous approaches at the industrial level in which large-scale syntheses of high-quality pristine graphene powder are proposed. Therefore, high volume fabrication methods of polymeric nanocomposites in which the chemical structure of graphene is preserved are highly desirable to spread the real applications of this nanomaterial in line with the planning of the European graphene framework. In this view, fundamental research should be rethought towards fabrication approaches that take into account their possible application in next future industrial advances. In perspective, this evolution may generate a revolution, making graphene technology cost-effective and widely spread with a significant positive impact on the society. The goal of MAGELLANO is to design, test, and digitally model the whole chain of processes within a manufacturing system to produce LabOnChip with embedded graphene-based electrochemical devices with increased performances. Moreover, the proposed approach is versatile so that it can be potentially used to produce every kind of electronics in big volumes, high quality, and low cost. To this aim, pristine graphene will be non-covalently bonded on plastic pellets through dry chemistry procedures and the obtained nanocomposites will be used in injection manufacturing fabrication methods. At the same time digital models able to describe the process will be developed. The project is based on four key features: 1) Definition of all the technological processes required to produce conductive graphene based nanocomposites, utilizing microinjection moulding and plastic particles covered with pristine graphene prepared adapting previously procedures already developed. 2) Electrochemical characterization of the nanocomposites and how these properties can be tuned. 3) Realization, from the beginning and refinement during the project, of a digital counterpart of the processes and of the manufacturing system to proactively identify the production alternatives for an effective and fast industrialization to guide the design of the single processes. 4) Fabrication of LabOnChip with the incorporation of nanocomposites electrochemical devices as a proof-of-concept application of the here developed approach.

Publications

.