Process Metallurgy and Simulation

Experimental facilities and simulation software for process metallurgy

Description:

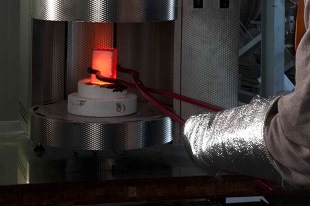

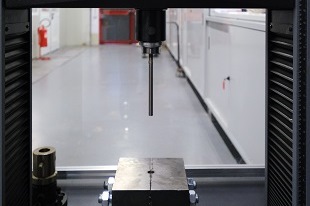

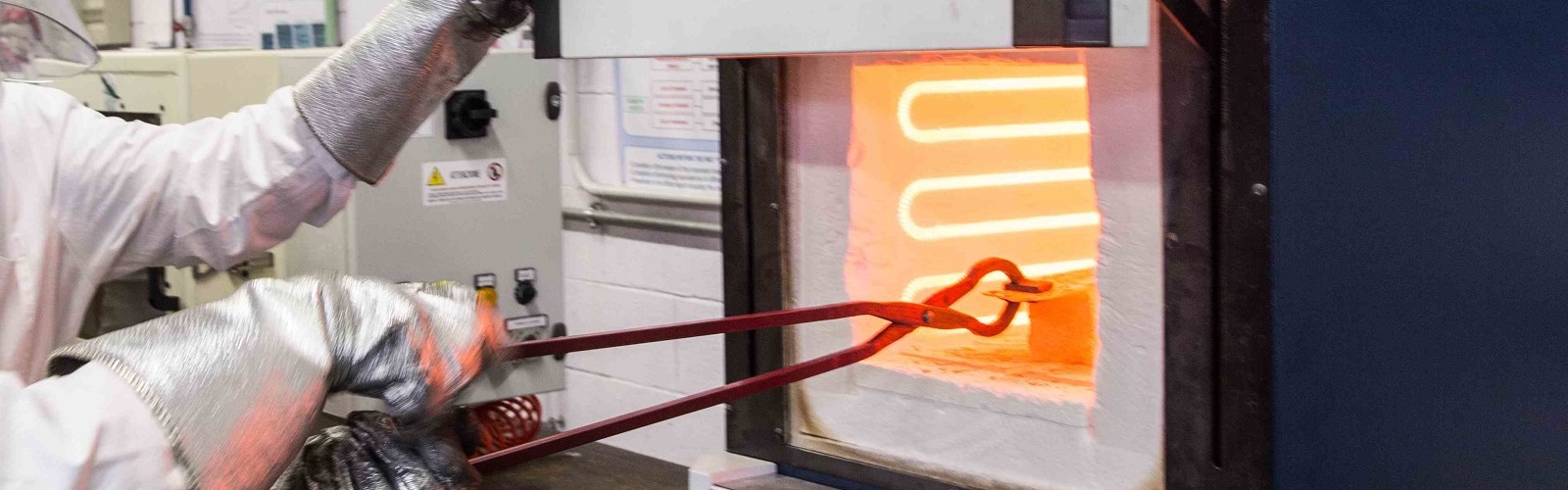

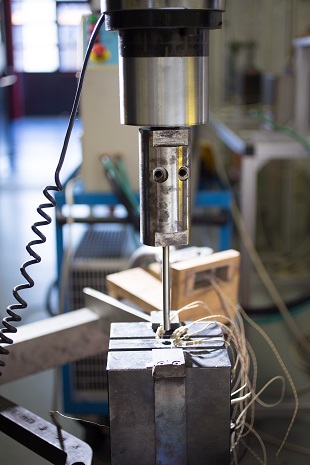

Numerical and experimental investigations on metallurgical processes are carried out by means of simulation software and lab-scale process facilities, including a set of muffle furnaces that can operate up to 1700°C in ambient or inert atmosphere, a melting resistance furnace, a rolling mill and a hot extrusion system for small billets and tubes. Equipment for handling, mixing and milling of metallic and ceramic powder are also available to researchers.

References:

Tenaris Dalmine, Siemens, Brembo, SMS-INNSE, Prysmian.

Instruments & Facilities:

- Thermocalc Software SUNLL licence for computational thermodynamics with DICTRA (Diffusion-Controlled phase TRAnsformation) and PRISMA (precipitation reactions) software modules are available to research in the Academic version. Thermodynamic and mobility databases are available for Fe, Al and Ni-based alloys

- Procast PRO-CT-01 with the following modules: GUI (VTS-CE-28), Thermal 2 core, Fluidynamic 2 core, Semisolid 2 core, Irradiation 2 core

- Deform DEFORMTM Premier, educational licence, version 11.3 with the following modules: Forming express, GeoTool, Integrated 2D3D, Inategrated Manufacturing, Inverse Heat, Material Suite

- Nabertherm melting furnace (temperature up to 1700°C, in ambient or inert atmospheres), internal diameter = 120, height = 130 mm, max load 2 kg

- Carbolite tube furnace (temperature up to 1050°C, in ambient or inert atmospheres). Internal diameter = 75 mm, uniform heated length = 540 mm

- Carbolite HRF 722D (temperature up to 750 °C), 220x200x495 mm

- Carbolite GPC 12/36 (temperature up to 1200 °C), 250x320x450 mm

- Lenton UAF 14/27 (temperature up to 1400 °C in ambient or inert atmospheres), 290x270x340

- OAM rolling mill (symmetric and asymmetric operation mode, cylinders of 150 mm diameter, speed: 0-20 rpm)

- MTS Exceed E45 equipped with induction coil, dies and plungers for cold and hot extrusion of small billets and tubes and for compaction of powder

- Retsch M400 ball mill system equipped with steel and alumina jars and balls

- Adler Powder mixer and sieving facilities

Activities:

- Simulation of metallurgical processes and heat treatments

- Laboratory casting of metallic alloys

- Rolling of metals at room and high temperatures

- Hot extrusion of small billets and tubes

- Hot and cold compaction of powder

- High energy ball milling of metal and ceramic powder

- Powder handling, mixing and sieving