The five-year LIS4.0 (Lightweight and Smart Structures for Industry 4.0), project, funded by MIUR (Ministry of Italian University and Research) under the "Departments of Excellence" initiative and launched in 2018, is now fully running. The MIUR funding is aimed at encouraging the activities of the Departments which stand out for the quality of research and for the scientific, managerial and educational planning; it is also aimed at stimulating research development plans with a view to "Industry 4.0". Consequently, the themes of the LIS4.0 involve a large part of the research, teaching and technology transfer activities carried out by the Department of Mechanical Engineering.

The main purpose of the LIS4.0 project is to strengthen and accelerate our research objectives within the Department’s core disciplines, integrated in a multidisciplinary perspective.

The field of sustainable mobility, one of the main challenges of our time, meets the study of materials, processes, technologies and integrated systems, along with the synergic use of virtual (simulation) and real (experimental) models and innovative monitoring and control methodologies based on IA and data mining, to develop vehicles and infrastructures with the following features:

made with light but performing materials, with unique properties, that are not obtainable from traditional materials but need to be designed ad hoc;

resulting from additive manufacturing processes with adaptive systems, which are able to 3D print by integrating sensors for in-situ and in-line monitoring and control.

smart, as they are able to read the context in which they are inserted, to interpret changes through sensors, to predict their results through fast and accurate modeling and to react and to correct themselves in a very short time, thanks to techniques of big data analytics and artificial intelligence.

It is precisely the Industry 4.0 paradigm where all the enabling technologies, key elements of MeccPolimi, are mixed up in a multidisciplinary kaleidoscope for the study of new, functionalized, smart and adaptive products, with applications to other sectors, such as biomedical, energy, space and mechatronics.

The first two years of the project saw the strengthening of the research staff (with the recruitment of international faculty, researchers and technical staff), the acquisition and commissioning of numerous new equipment, as well as the consolidation of projects related to top-level educational activities (second and third level of university education).

The proposal submitted to MIUR, which received one of the highest scores, provided relevant funding, accounting for 9.350.000 € (70% already invested in the first two years); more than 3.200.000 € have been already used for the acquisition of new research equipment. MeccPolimi supported in co-financing the expansion and restructuring of the laboratories; the complete commissioning of the new equipment was thus realized within the initial two years.

The research lines have been divided into four technological challenges and related Work Packages.

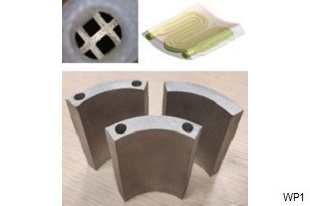

The technological challenge faced in WP1 (Smart Metal additive manufacturing for functionalized 4D structures) is intended to apply AM as a new way to produce lightened, functionalized components, including 4D structures, through a combination of new design, new materials and "smart" solutions for monitoring and control of additive manufacturing processes. The new equipment will allow the analysis and characterization of geometry and flowability of metal powders, the development of new additive processes, such as extrusion-based Additive Manufacturing (EAM), along with the sensoring and instrumentation of an advanced SLM system for the development of in-process monitoring. This will enable the study of control and in-line correction of the process. Finally, the qualification of the performance of the final product will be carried out using the latest generation equipment, including SEM microscope, a quantometer, as well as a dilatometer and a Laser Flash equipment to evaluate the thermal properties of materials at various temperatures.

The pads of a tilting-pad bearing functionalized by creating shaped ducts for their cooling are an example of this technology. The product has already been tested on the Department's oil-film bearing test bench and has shown how it is possible to reduce the oil flow for the same bearing performance.

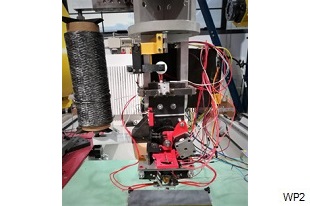

The WP2 (Smart structures in composite material) is dedicated to the study of long-fiber composites, which offer significant advantages in terms of lightness and performance providing the ability to absorb the kinetic energy resulting from impacts. The planned activities (concerning the development of sensorized extruders and moldless BAAM - Big Area Additive Manufacturing - additive technology based on the use of two cooperating anthropomorphic robots) will allow the realization of a pilot plant demonstrator with BAAM moldless 3D printing system for construction of long carbon fiber components that contain optical fiber for monitoring and diagnostics.

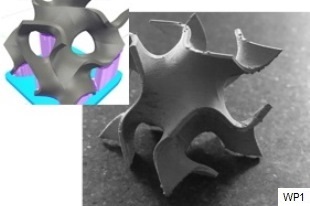

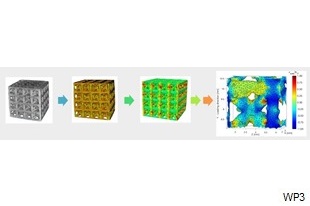

The WP3 (Meta-structures) is aimed at analyzing the performance and applications of metamaterials obtained by combining periodic cellular structures in order to obtain artificial structures with new characteristics, different than those available in nature: these structures depend on both the composition and the geometry developable on different dimensional scales.

Research activities include the development of appropriate calculation models, mechanical characterization, analysis of the applications of cellular materials and latex, up to the development of compact cell meta-materials for the isolation of structural and acoustic vibrations and usable as element for the production of components for mechanical and aerospace applications.

The WP4 (Autonomous systems) is dedicated to the development and application of innovative technologies in the field of future transport. In particular, it is aimed at developing safety systems (ADAS) and autonomous driving connected by the development of automation algorithms and the creation of a communication system between vehicles and infrastructure (V2X). It aims at verifying the actual benefits due to the use of innovative technologies in the construction of the vehicles (lighter materials or with better heat exchange and sound-reflection properties studied and developed in the other WPs). Finally, it aims at evolving these technologies focusing on the central role of the human being, hence the attention to comfort and the development of HMI interfaces. The different activities will take advantage of a prototype vehicle (EasyMile EZ10) designated as a demonstrator for the different activities.

The expected impacts of the LIS 4.0 project, linked to the deepening of knowledge on topics at the front-end of technology, are expected to provide further improvement in the positioning of the Department in the international context and an increase further the collaboration with Italian and foreign industrial partners.