The High Strain Rate Lab started operating in 2021 and is included in the interdepartmental lab network. HRS offers skills and equipment about material and component behaviour under high-speed deformation (i.e. high strain rate). The Departments involved are the Department of Mechanical Engineering, the Department of Aerospace Science and Technology, the Department of Civil and Environmental Engineering and the Department of Electronics, Information and Bioengineering.

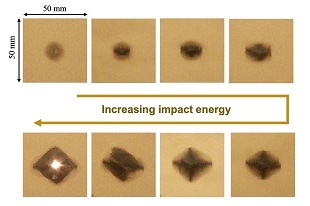

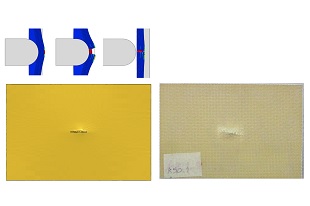

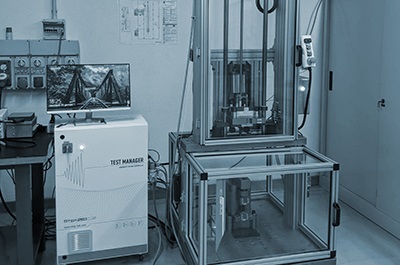

In particular, the activities offered at the Lab focus on the dynamic characterisation of different types of materials and structures operative in the fields of mechanical, civil, aeronautical, and electronics engineering. More specifically, it is also possible – among others – to carry out impact tests on structures made of polymeric, composite, metallic, and cementitious materials, possibly through sensors. Among the available equipment, a new Drop-Tower machine to carry out characterisation tests of extreme relevance in controlled environments and with a series of measurement systems able to monitor impact-related physical quantities. The system is an important research instrument when defining advanced design methods for extreme loading conditions. The possibility to have an instrument allowing to carry out repeatable impact tests, as well as with a high-accuracy level of measurements, might turn into having an intermediate level (in the definition of predictive methods), between the material calibration phase and full-scale tests. More precisely, the instrument is highly indicated to carry out activities to evaluate the damage caused by low-velocity impacts.

Lab equipment:

- Drop tower to carry out drop weight impact tests designed up to 700 J of impact energy. The system measures the main physical quantities involved with a sampling frequency up to 3.5 MHz. It is possible to use weights of about ten kg with impact forces of about 90 kN. The equipment includes several instrumented strikers that can carry out tests according to the following standards: EN 12390-1/EN 12390-5, ASTM 7136, ASTM 3763, ISO 6603, ISO 8256.

- Reversal High-speed tensile testing machine. Also included in a drop tower, the machine allows to carry out high-speed tensile tests (speed 10 m/s power >30 kJ).

- Gun for impact testing 1. Masses from 20 kg to 150 g. Size up to 50 mm in diameter. Speed limit to 200 m/s.

- Gun for impact testing 2. Masses up to 2 kg. Size up to 120 mm in diameter. Speed limit to 200 m/s.

- 3 Strainbook acquisition systems. Sample frequency aggregated 1 MHz. Each has eight channels. Signal conditioning for pressure, acceleration, and deformation.

- High-speed camera.

Offered services:

- Testing according to the following standards: EN 12390-1/EN 12390-5, ASTM 7136, ASTM 3763, ISO 6603, ISO 8256;

- Low and high-speed impact testing on coupons and components.

The Department of Mechanical Engineering plays an active role in the lab activities thanks to Prof. Andrea Manes and his research group working on “Structural integrity under extreme loading conditions”. More specifically, the group is involved in defining predictive methods to design structures subjected to extreme loadings like impacts, explosions, extensive deformations, failure, and more. Here’s the list of our Ph.D. students part of the research group and active in HSR: Mohammad Rezasefat Balasbaneh, Álvaro González Jiménez, Luca Lomazzi and Alessandro Vescovini.