PoliNDT is an interdepartmental laboratory of the Politecnico di Milano and involves the Department of Chemistry, Materials and Chemical Engineering (DCMC), the Department of Electronics, Information and Bioengineering (DEIB), the Department of Civil and Environmental Engineering (DICA) and the Department of Mechanical Engineering (DMEC). The laboratory was born to explore and apply innovative non-destructive and diagnostic techniques in the fields of Civil and Mechanical Engineering and it is meant to be a link between the Academy and the productive world in the field of DIAGNOSTICS and DURABILITY, as well. The main objective is the experimental application on site, also through the cooperation of many other infrastructures of the Politecnico di Milano, such as the The Testing Laboratory for Materials, Buildings and Civil Structures.

Three are the laboratory’s key words: research, services and training.

Research is the core business of PoliNDT. The aim is to find out effective innovative solutions to unconventional issues. The expertise of the involved Departments is different and complementary at the same time, allowing the onset of new research lines, including for example:

- integration and improvement of consolidated diagnostic methodologies for the application to different types of materials and structures;

- development of sensors and innovative or low-cost instruments, by integrating the expertise on diagnostic methods and monitoring with the physics of sensors and analogic/digital electronics;

- automation of inspections for large structures and/or dangerous or non-accessible environments.

Services for in situ diagnostics, with particular focus on issues that cannot be solved by standard procedures and methodologies. In particular, some examples are:

- technical assessments, by non-destructive techniques, of metallic, polymeric, wooden, masonry, concrete and composite materials and structures;

- assessments of damaged structures (by overload, corrosion, earthquake, fire, etc.);

- development and integration of non-destructive techniques for the diagnostics on civil and mechanical engineering components;

- development of innovative and low-cost sensors and instruments;

- automation of inspections of monitoring systems.

Training, in order to improve teaching activities with new ideas in the field of structural and monitoring diagnostics and to transfer the learned knowledge to the interested people.

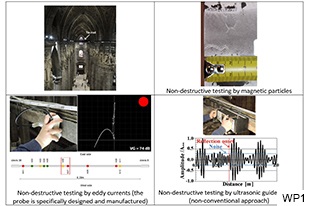

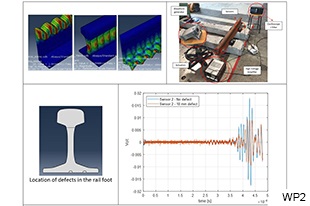

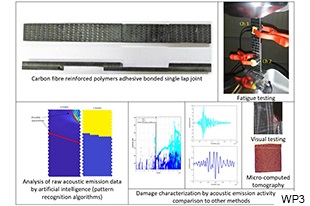

The laboratory is equipped with a wide range of instruments for structural diagnostics in terms of experimental stress analysis (optical and electric strain gages, photo elasticity, etc.), non-destructive testing (visual, liquid penetrants, magnetic particles, ultrasonic, eddy currents, etc.) and structural health monitoring (ultrasonic guided waves, acoustic emission, etc.).

Most recent acquisitions include: a measurement system for acoustic emissions, a low-frequency ultrasonic tomographic system using shear waves, an iconic chromatograph and a pulsed laser source for generating elastic waves.

Some examples of activities carried out up to now are:

- real-time monitoring of the structural integrity of railway rails by means of techniques based on ultrasonic guided waves (Figure 1);

- identification of defects in the historical tie-rods of the Duomo of Milan by means of different methodologies of non-destructive testing (Figure 2);

- real-time monitoring of the structural integrity of composite bonded joints by means of techniques based on acoustic emission (Figure 3).

The Department of Mechanical Engineering has an active part in the laboratory thanks to Prof. Michele Carboni, who has been carrying out researches on non-destructive diagnostic techniques for years and is qualified and certified as NDT inspector (Level 3 ISO 9712) in the following methods: visual, liquid penetrants, magnetic particles and ultrasonic. Moreover, the extension of certification for railway maintenance in the visual, magnetic particles and ultrasonic methods, according to ANSFISA 02/2012 guidelines and their review U.0015992, is available, as well.