Nowadays, composite materials are increasingly replacing conventional light metal alloys for many different applications including also critical load carrying components. The heterogeneous nature of composite materials and also their infinite combinations make them adaptable to a large variety of application fields since their properties can be a priori tailored to specific tasks. However, this peculiarity leads to a large variability in mechanical properties and failure modes. In fact, due to the heterogeneous nature of composite materials, engineers face new failure mechanisms different from the long-studied failure processes of traditional materials. Composite materials can suffer from different types of fibre failure (e.g., breakage and kinking) as well as from several matrix damages depending on the state of stress. Additionally, and differently from traditional materials, laminates can experience interlaminar failure. The correct description of mechanical properties, including failure mechanisms, requires material models based on many parameters. Complex experimental procedures are therefore needed to define these parameters. DMEC has great expertise in doing calibration of mechanical properties of composite materials thanks to the availability of numerous instruments and test devices able to investigate into the composites’ mechanical behavior, from the coupon level to real parts.

Specifically tests on polymeric and composite materials can be carried out in DMEC lab:

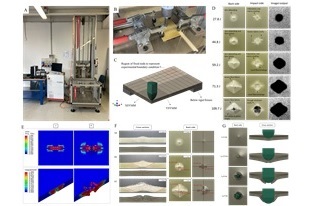

- Static tests on composite materials according to ASTM standards

- (e.g. D6671, D5379, D6484, D695, D3410) and ISO (e.g. 14126, 14129)

- Static tests on polymeric materials according to ASTM (e.g. D3039, D3518, D638) and ISO 527

- Low cycles fatigue tests (LCF) and High cycles fatigue (HCF), e.g. ISO 13003

- Other kinds of test (e.g. ISO 178, ASTM D7274) or test conditions (high/low temperature, standard) can be arranged upon request

- Adhesive testing (static e.g. ISO 14130, ISO 15024 and fatigue)

- In collaboration with the interdepartmental laboratory HSR, it is also possible to perform dynamic characterization tests according to the ASTM D7136, D3763, ISO 6603, ISO 8256 standards exploiting a brand-new drop tower

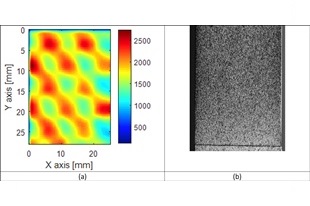

- Full field strain measurement on composite specimens by Digital Image Correlation

Other customized tests can be carried out.

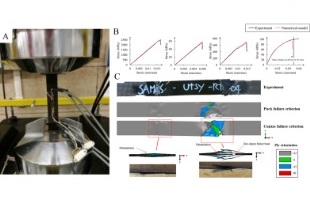

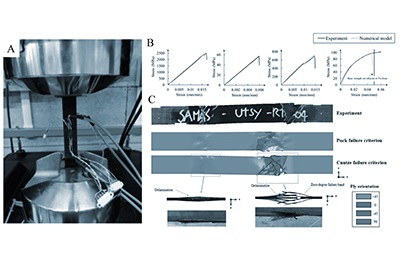

Moreover, the understanding of the failure processes of composite materials has pushed global research to develop reliable and effective material models in numerical modeling environment. These models are expected to replicate the complete constitutive stress–strain relationship, starting from the loading phase passing through the failure onset and finishing with damage propagation and ultimate failure. DMEC has also a great expertise in calibrating mechanical properties of composite material by means of a mixed approach that replicate experimental test in a numerical modelling environment (inverse method). This allows for an accurate, scalable, and transferable calibration to be obtained. It is not just a tuning process but a tailored procedure that allows for reliable material cards to be obtained and to be used inside effective modes even for large structures. Finally, a collaboration with the “High Strain Rate” Interdepartmental laboratory allows also for an insight into dynamic mechanical properties of composite materials.