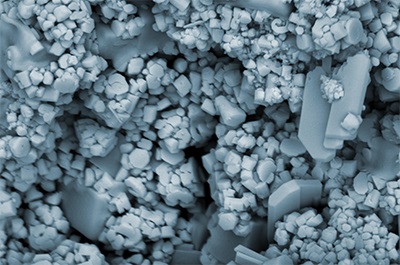

European industry generates 1.3 million tonnes of Electric Arc Furnace (EAF) and 50 ktonnes of Cupola Furnace (CF) dusts annually, both considered hazardous waste, which could be an alternative source of valuable metals essential for low carbon industry (they contain, for instance, Zn, Cd, Cr, Ni, Pb...).

About 30 steelworks in the ESEE RIS region operate EAFs for steel scrap-based steel production. No

recycling plant operates in the ESEE region, so the dust generators have additional costs of transporting the dust to the nearest Zn recovery plant. Landfilling of metallurgical dust is in many RIS countries forbidden due to the presence of toxic substances.

In RIS region, knowledge for extraction of a narrow range of EAF dust compounds exists, and also the utilisation of residues uses in construction industry.

RIS-DustRec-II project aims towards capacity building for:

- effective recovery of all economical compounds of the dusts (Zn, Pb, Cu, Fe and others);

- minimal waste discharge;

- economic feasibility with improved environmental and social impacts.

The proposed innovative approach involves combining emerging techniques from innovative magnetic and gravity separation methods to new pyro and hydrometallurgical reprocessing technologies for the separated fractions. More than 10 locations in 5 RIS countries will be sampled and tested, and the business potential of the EAF and CF dust multicomponent recycling technology. The goals will be also achieved by promoting an active inclusion of higher education students in development of feasible recovery technology that generates minimal waste discharge and improve environmental and social impacts. Eight partners are currently involved, with seven public and private research centres and universities and one industrial partner, coming from Slovenia, Italy, Serbia and Poland (Jožef Stefan Institute (JSI); Jožef Stefan International Postgraduate School (IPS); TH Re-MINING d.d.; Politecnico di Milano; Institute for technology of nuclear and other mineral raw materials (ITNMS); University of Belgrade and Lukasiewicz Research Network - Institute of Non-Ferrous Metals (L-IMN)).