The applied metallurgy research group focuses on two main group of activities:

- optimization of metal alloys and industrial processes to produce mechanical parts;

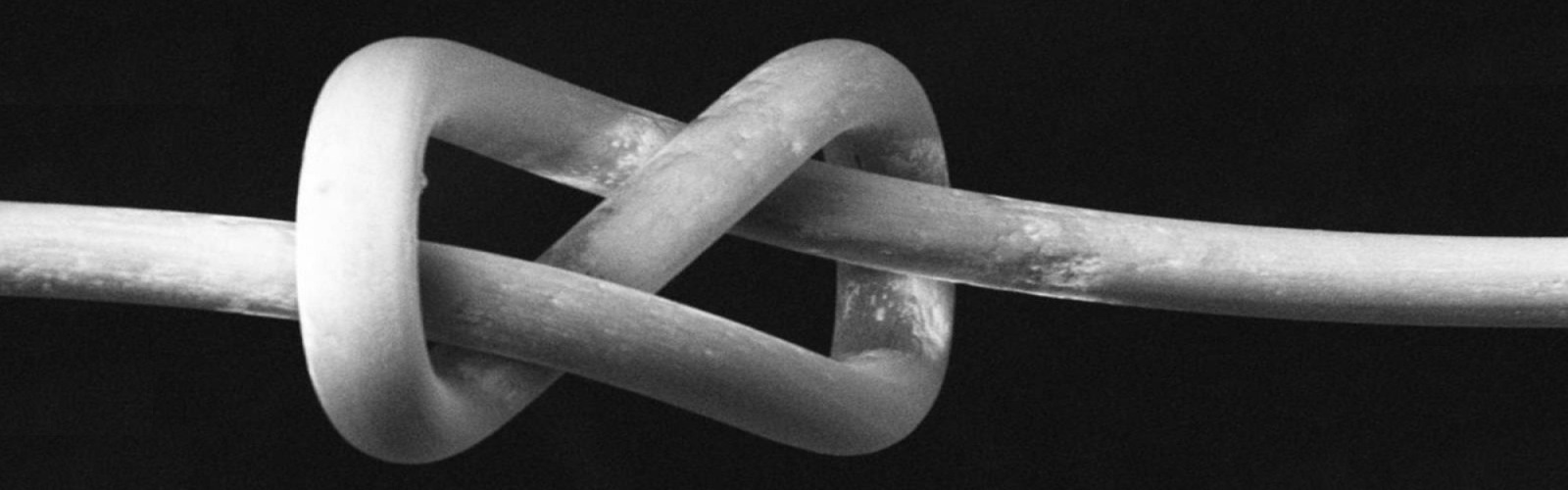

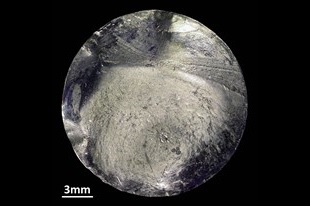

- Failure Analysis of components, machineries or industrial plants showing problems during service.

Focusing the attention on material properties is crucial for the accurate selection of engineering materials in order to target desired functionality at the set budget.

Similarly, applying an analytical process-based knowledge to pay attention to the damage phenomena involved is an effective way to seek cost-effective solutions to enhance the reliability of the product to meet the needs of the market. Applying both approaches, widely used in applied metallurgy, leads to turning the customer’s needs into a request of materials able to give support throughout the whole design phase successfully.

Having knowledge about materials and their properties is also very important when it comes to Failure Analysis because allows to identify the causes of failure and prevent new ones. These types of activities always require a multidisciplinary approach, which also includes applied metallurgy due to its central role.

Similarly, applying an analytical process-based knowledge to pay attention to the damage phenomena involved is an effective way to seek cost-effective solutions to enhance the reliability of the product to meet the needs of the market. Applying both approaches, widely used in applied metallurgy, leads to turning the customer’s needs into a request of materials able to give support throughout the whole design phase successfully.

Having knowledge about materials and their properties is also very important when it comes to Failure Analysis because allows to identify the causes of failure and prevent new ones. These types of activities always require a multidisciplinary approach, which also includes applied metallurgy due to its central role.